At Nextpack, we understand that exceptional packaging and product design go beyond aesthetics—it’s about creating an experience for customers. With over two decades in the business, Nextpack has mastered the art of combining clever design with efficient processes to deliver solutions that make products stand out in competitive markets. Whether it’s premium packaging or product design, our methodical approach ensures each project is meticulously handled from start to finish. Here’s a closer look at how our process unfolds.

The Packaging Design Process

When it comes to packaging design, each project starts with a thorough understanding of the product and its unique needs. Our six-step approach ensures that every element—from materials to functionality—is thoughtfully considered.

1. Briefing

The first stage is all about discovery. We ask key questions to understand the purpose and requirements of the packaging:

- What product needs packaging?

- Will it be sold on retail shelves or online?

- How durable does the packaging need to be?

- How accessible should the product be?

- Are there specific design elements you envision? (e.g., colours, finishes, opening styles)

- Are there dimension limitations? (e.g., shelf heights, postal restrictions)

- What is the budget?

- What are the primary shipping methods? (e.g., sea freight, air freight, express post)

- Are there environmental factors like humidity or temperature variations to consider?

This information helps our design team make practical and creative decisions, ensuring the packaging aligns with your goals.

2. Concepting

With a clear brief, we move into the concepting phase, which includes:

- Collaboration between our creative team and manufacturing partners.

- Discussing materials, specifications, and sustainability options.

- Envisioning the end-user experience to ensure the packaging is both functional and appealing.

- Designing concepts that fit brand identity and budget.

- Selecting the right cardstock for durability and aesthetics.

- Engineering structural integrity to withstand handling during transit.

- Optimising accessibility while ensuring security to deter theft.

- Strategic sizing to minimise shipping costs or enhance perceived value.

This phase ensures that the packaging is not only visually appealing but also practical and durable.

3. Sampling

Once we have a solid concept, we bring it to life through mock-ups. This step allows us to test functionality:

- After pricing is finalised, we create blank samples for review.

- Clients can see, feel, and test the design.

- Adjustments are made if needed, and we re-sample until perfection is achieved.

- Testing ensures the packaging withstands shipping conditions.

- Once the structure is finalised, die lines are provided for artwork application.

- A printed sample is available for an additional fee to preview the final design.

This thorough process guarantees that every detail is refined before mass production.

4. Bulk Production

With the design finalised, we move to bulk production:

- Orders are placed, and manufacturing begins.

- Quality control checks are conducted at various stages.

- Production samples are reviewed for consistency.

This ensures that the final product meets all functional and aesthetic expectations.

5. Shipping

Once production is complete, we ensure efficient and secure shipping. Our logistics team handles international freight, customs clearance and local delivery.

- Goods are reinforced and packed appropriately to prevent damage in transit.

- The most economical or optimal freight method is selected (sea, air or express).

- Our seasoned clearance agents are engaged to avoid customs hassles and delays.

- We provide real-time shipment and delivery status so you have a clear understanding of when you’ll receive your goods.

6. Delivery

The final step ensures your packaging arrives in perfect condition.

- We only work with highly experienced and reputable freight forwarders who handle our deliveries with care.

- Our logistics team works closely with you to deliver directly to your warehouses, retail stores, or distribution centres.

- On the pulse Post-Delivery Support is available to assist with reorders and future modifications.

This structured approach guarantees a seamless process from design to delivery.

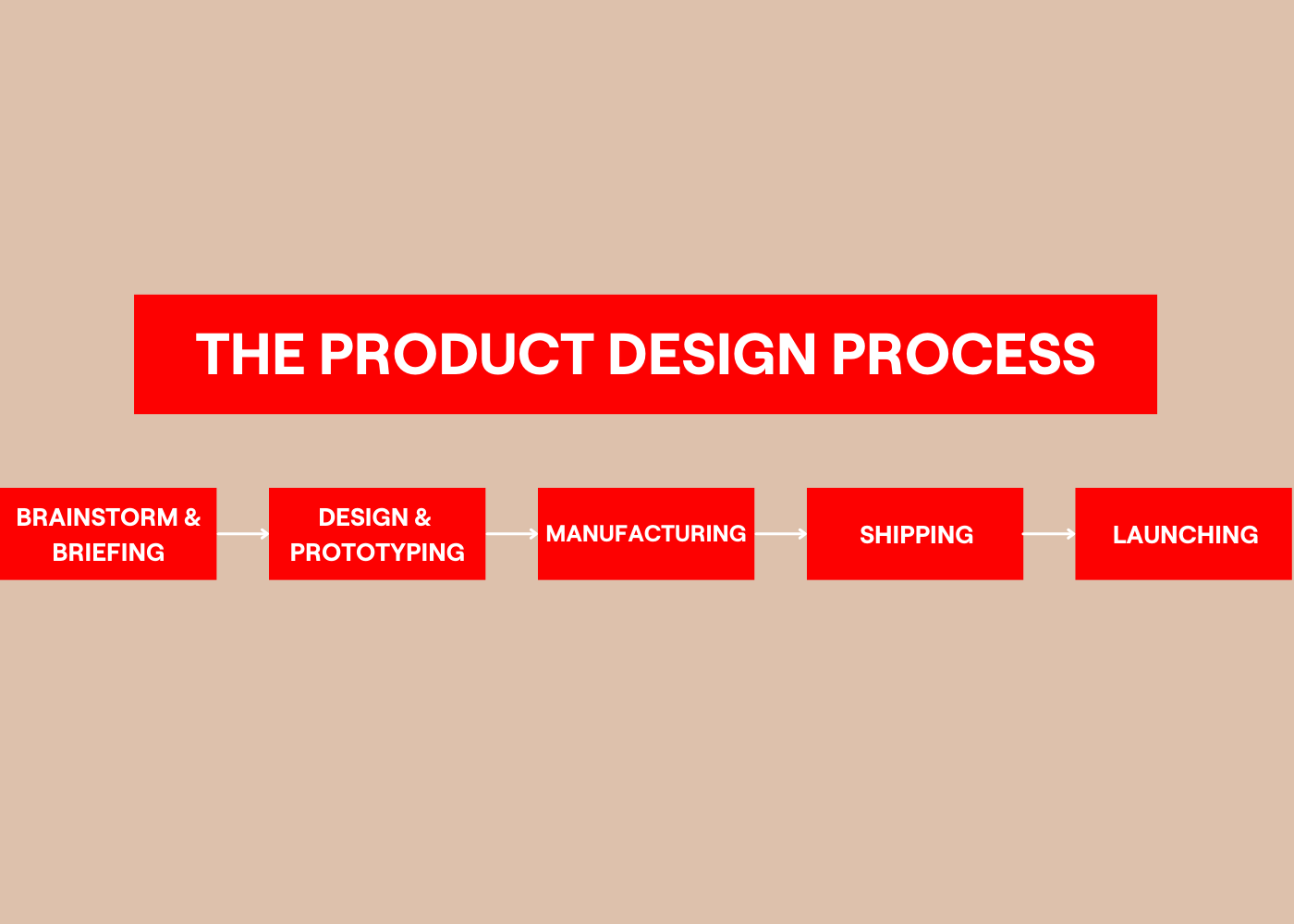

The Product Design Process

For clients interested in product design, Nextpack offers a streamlined, five-stage approach. Each stage transforms ideas into market-ready products that meet both brand and customer needs.

1. Brainstorm & Briefing

The product design journey begins with brainstorming:

- Researching market trends and gathering client feedback.

- Developing concepts that solve real customer problems.

- Identifying potential shipping challenges early to ensure smooth delivery.

This stage ensures the product concept is viable and grounded in customer needs.

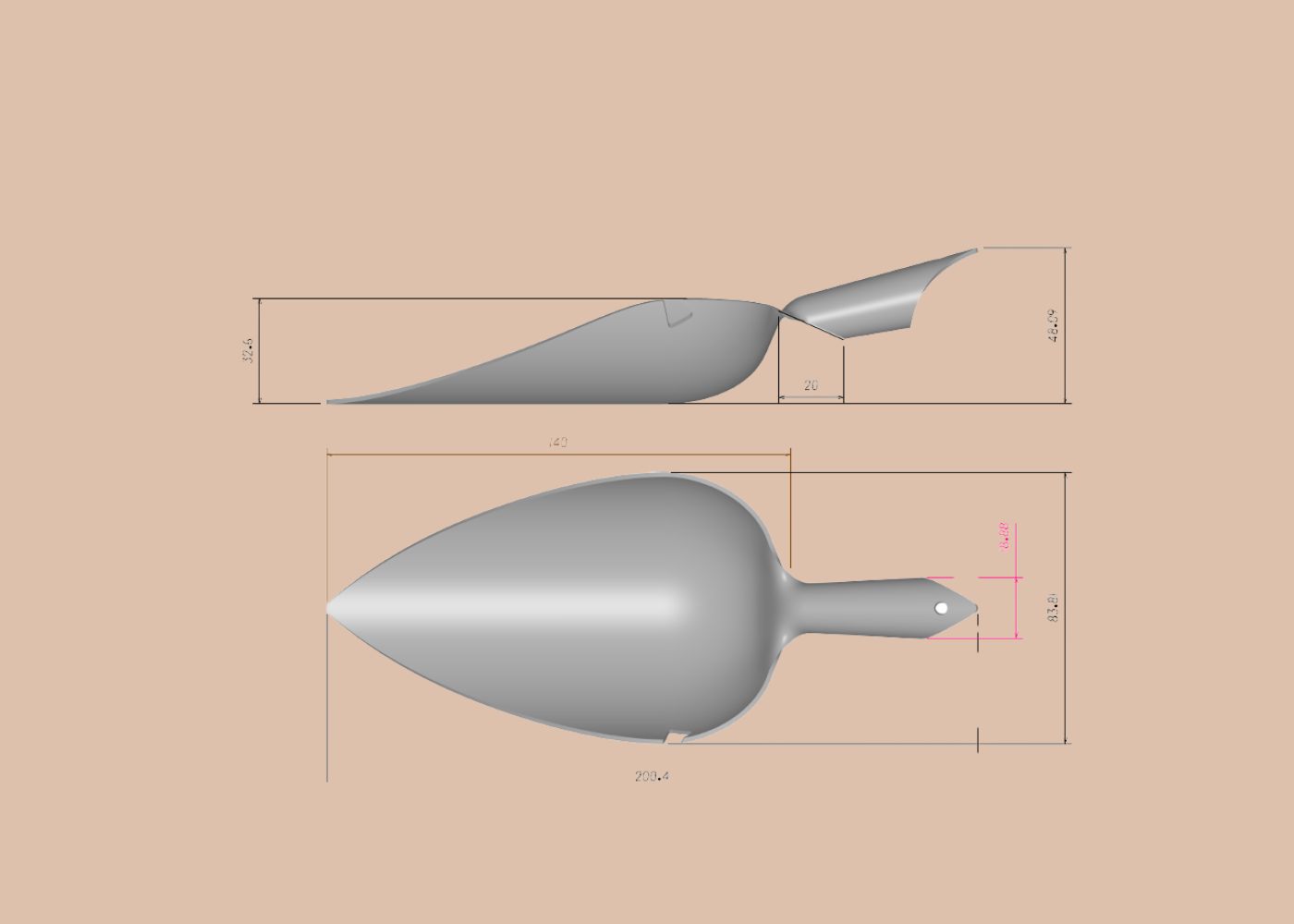

2. Design & Prototyping

With a concept in place, we move into detailed design:

- Creating product specifications for development.

- Producing tech drawings for moulds where necessary.

- Carefully selecting optimal materials to execute the design.

- Crafting and refining prototypes based on feedback.

- Conducting user testing to ensure functionality and quality longevity.

This phase is iterative, refining the product until it meets all requirements.

3. Manufacturing

The manufacturing phase focuses on precision:

- Selecting trusted suppliers for quality assurance.

- Leveraging manufacturing partnerships spanning 5-20 years.

- Optimising production lines for efficiency.

- Choosing suitable manufacturing seasons to avoid weather impacting product quality.

- Following rigorous quality control procedures refined over many years.

4. Shipping

Once production is complete, we manage logistics:

- Goods are appropriately packaged to reduce damages in transit.

- Cost-effective and reliable shipping methods are chosen.

- We handle all customs clearance and import related documentation to ensure a smooth entry into the country.

- You’ll be provided with regular updates throughout the process so you are clear on exactly when you’ll have your stock.

This guarantees products arrive safely and on time.

5. Launching

The final stage is bringing the product to market:

- Strategic planning and marketing for a successful launch.

- Supply of final samples for marketing, photography and sales teams.

- Delivering a high quality product designed with customers in mind.

This step marks the culmination of months of planning and innovation.

Conclusion

At Nextpack, great packaging and product design require more than just creativity. Our commitment to quality, efficiency, and collaboration ensures we create impactful solutions for our clients. Through structured processes, we help brands achieve their goals and make lasting impressions in the marketplace.