In 2026, eco-friendly packaging is no longer a differentiator. It is a baseline expectation. Customers are paying closer attention to what arrives at their door, how it is made and where it ends up. Regulators are tightening requirements. Retailers are asking harder questions about recyclability, on-pack recyclability labels and waste.

Brands that treat sustainability as a side note risk falling behind. In contrast, brands that weave sustainability into their packaging from the start are building trust, loyalty and long-term resilience.

Here at Nextpack, we see this shift play out every day. The brands making the most meaningful progress aren’t chasing quick wins or superficial “eco-friendly” gestures. Instead, they are committing to thoughtful, commercially grounded changes in how they design, specify and manufacture their packaging.

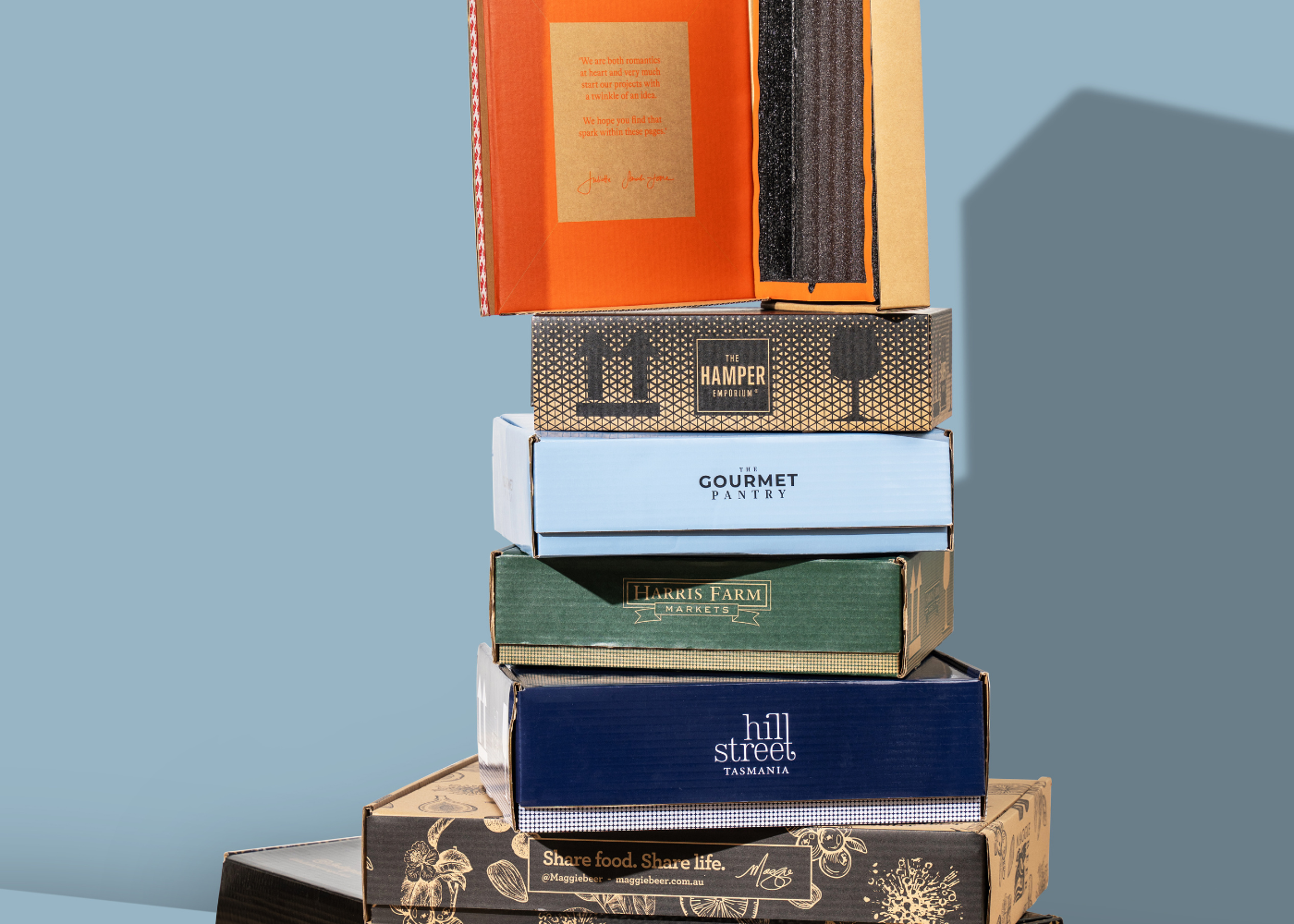

We’ve seen this firsthand across the work we’ve delivered for clients including Boody, Villeroy & Boch, The Hamper Emporium, YETI, Maggie Beer, Bourke Street Bakery, Lark Distillery, Callington Mill Distillery, Weleda and more – brands that understand sustainability is not a trend, but a long-term strategic advantage. From refined fibre-based protective systems to recycled-board gift packaging and biodegradable print finishes, each project reflects a deliberate shift toward packaging that performs commercially while respecting environmental expectations.

If you are ready to align your packaging with modern sustainability standards – and do it in a way that still feels premium and on brand – these seven eco-friendly packaging ideas for 2026 will help. We explore practical ways to reduce impact, improve recyclability and protect your products, supported by examples from real projects we have delivered at Nextpack.

1. Use sustainable packaging materials that are recycled, recyclable and biodegradable

As sustainability shifts from a trend to an expectation, the materials you choose are no longer a behind-the-scenes technical detail – they’re a core part of your brand story. Customers notice when packaging feels aligned with the values a brand communicates. They also recognise when materials contradict the message. Recycled substrates, biodegradable coatings and renewable inks now play a critical role in strengthening credibility, reducing environmental impact and shaping a more premium sensory experience.

A great example of this in practice is our collaboration with Boody, the ethical essentials brand. Their commitment to conscious design extends beyond their bamboo-based garments and into their packaging. Together, we developed recyclable shipping boxes and inner packaging printed with vegetable-based inks – replacing petroleum-based alternatives with renewable, low-impact options. This approach ensures every customer touchpoint reflects the brand’s authenticity, care and environmental values.

As consumer expectations evolve, sustainable material choices do far more than reduce impact. They strengthen trust, reinforce positioning and elevate perceived quality. If you’re interested in why eco-friendly substrates often feel more premium, our article Beauty Packaging Psychology: Design That Sells explores the emotional cues behind material selection and how sustainability influences purchasing decisions.

For brands reviewing their own material choices, our materials page offers a comprehensive look at recycled cardboard, vegetable-based inks, glass, metal, biodegradable plastics and sustainably sourced wood. These insights can help you understand what’s possible across different product categories and where the biggest sustainability wins can be made.

2. Print with vegetable and soy-based inks

Sustainable packaging isn’t only about substrates. What you print with matters just as much. Traditional petroleum-based inks release Volatile Organic Compounds (VOCs) during production and disposal, complicate recycling streams and often undermine sustainability claims – even when the rest of the packaging is fully recyclable.

Vegetable and soy-based inks offer a cleaner, more responsible alternative. Made from renewable resources, they significantly reduce VOC emissions, improve the recyclability of paper and cardboard, and still deliver excellent print performance. In many cases, they produce richer colour saturation and sharper detail, enhancing both brand presence and perceived quality.

These inks also help brands maintain a consistent sustainability narrative. Our client, Alpha-H, an iconic Australian skincare brand, uses vegetable-based inks across their cartons to support their clean-beauty ethos. The inks complement their recyclable tubes and responsibly sourced paperboard, creating a cohesive packaging system that feels intentional from every angle.

Beyond environmental gains, ink choice also influences how colour, texture and finish are perceived. If you’d like to explore how these elements shape the emotional impact of packaging, our article Three Powerful Design Elements – The Power of Fonts, Colours, and Textures in Packaging Design offers a deeper look at how print decisions elevate the overall brand experience.

3. Right-size your packaging

We’ve all experienced it: ordering a single item online, only for it to arrive in a box three times its size with unnecessary filler spilling out. It’s frustrating for customers – and wasteful for the planet. Oversized packaging remains one of the most common and overlooked sustainability issues in e-commerce. It creates excess waste, increases shipping costs and amplifies carbon emissions due to inefficient pallet loading and heavier freight. Ultimately, it’s a lose-lose for both brands and the environment.

At Nextpack, we approach every packaging brief with precision and restraint. Packaging should protect what’s inside, feel on-brand and avoid unnecessary materials – without compromise.

A clear example is our work with The Hamper Emporium. They needed packaging that delivered both protection and polish without relying on bubble wrap or foam. We developed custom hamper boxes tailored to their product configurations, refining every structural detail to reduce material consumption while maintaining strength, efficiency and a premium unboxing moment. You can explore this project in more detail in our case study.

A similar efficiency-led approach shaped our solution for Villeroy & Boch. Their porcelain dinnerware range required adaptable protection across multiple plate and bowl sizes, each with subtle dimensional differences. Rather than relying on bulky padding, we engineered a spring-based recycled cardboard insert that flexes to varying depths while remaining fully kerbside recyclable. This structural design strengthens protection, reduces waste, streamlines production and elevates the unboxing experience. For a closer look at how this came to life, you can read our full Villeroy & Boch case study.

If your brand is exploring more efficient formats that balance sustainability with presentation, Custom Packaging Solutions for Premium Products: What Leading Brands Need to Know offers helpful insight into how structure, material and product mapping can work together.

Smart packaging design reduces costs, improves logistics and minimises your environmental footprint – all while delivering a more intentional experience to your customers. In short, right-sizing isn’t just the sustainable choice. It’s the strategic one.

4. Replace plastic protective barriers with fibre-based structures

Protective packaging is essential, yet traditional solutions such as foam blocks, Expanded Polystyrene (EPS) inserts and plastic trays are increasingly out of step with modern sustainability expectations. Foam is difficult to recycle at scale, and plastic trays often end up in landfill due to contamination or limited local processing capability. Customers also notice when internal components feel inconsistent with the rest of a brand’s sustainability story.

Fibre-based structures provide a strong, future-focused alternative. Corrugated cardboard and engineered board can be die-cut, folded and layered to cradle products, absorb impact and guide the unboxing experience. Just as importantly, these materials are widely recyclable through kerbside systems, making them both practical and planet-friendly.

In our work at Nextpack with distilleries and premium beverage brands, we frequently replace foam bottle cradles with custom corrugated inserts. These engineered structures hold bottles securely in transit while keeping the entire pack fully fibre based. The result still feels premium and purposeful while offering a significantly improved environmental profile.

A recent example is our Lark Whisky display box, created for their award-winning Tasmanian single malt. Instead of relying on foam or mixed substrates, we designed a high-end fibre-based system made from 70% recycled board, complete with a subtle textured surface and refined gold-foil detailing. The insert secures both whisky bottles and Glencairn glasses with precision, delivering protection, aesthetic detail and curbside recyclability in a single cohesive structure. You can explore the full project in our Lark Whisky case study.

If your packaging currently depends on foam or plastic components, reviewing your internal structures is one of the most impactful sustainability upgrades you can make. Many brands are surprised by how robust, efficient and visually refined fibre-based alternatives can be. And if you’re exploring ways to elevate the user experience alongside material changes, our article How to Create Memorable Unboxing Experiences is a helpful companion resource.

5. Rethink lamination and coatings without losing a premium feel

Traditional matte lamination is often used to create a smooth, premium finish. However, it is typically a plastic film that cannot be recycled, making it increasingly incompatible with modern sustainability standards. As expectations shift, brands are looking for alternatives that protect the packaging, feel elevated and remain kerbside recyclable.

A strong example of this shift is the Maggie Beer Living Range, where we replaced plastic-based laminates with biodegradable and recycled card swing tags printed using vegetable-based inks. You can see how this approach comes to life in our Maggie Beer Living case study, where these sustainable materials deliver warmth, tactility and durability while maintaining a refined, premium feel.

Premium doesn’t need to rely on plastic finishes. If you are exploring how to elevate texture, tone and perceived value without lamination, our article Mastering Elegance: Crafting Luxury Packaging on a Budget breaks down high-end coatings, textures and materials that offer a sophisticated feel while remaining fully recyclable.

6. Embrace mono material design for easier recycling

Mono material packaging uses a single primary material throughout the structure. For example, a carton made entirely from paperboard, without plastic windows, metallic laminations or composite layers.

This approach simplifies recycling for both customers and facilities. When there is no need to separate layers or remove complex components, the likelihood of successful recycling increases.

Mono material design also supports clearer communication. When you can confidently tell customers that an entire pack can go into paper recycling, you reduce confusion and build trust.

We see mono material solutions gaining momentum across beauty, personal care, home fragrance and fine food. Brands are choosing to forego some historical embellishments – such as plastic windows or heavy foils – in favour of thoughtful printing, embossing, debossing and cut outs that still deliver a strong identity.

Digital and structural techniques now offer many ways to add depth and texture without compromising recyclability. For example, a blind emboss over a rich, tactile board can feel just as premium as a heavy plasticised finish.

At Nextpack, we work with clients to strip back unnecessary complexity. The aim is not to remove all detail, but to prioritise details that carry meaning and minimise those that impede circularity.

7. Invest in a materials audit to create a long-term roadmap

Many brands want to move toward more eco-friendly packaging but are unsure where to begin. Different products, regions and channels often use different packaging solutions, making the picture feel fragmented.

A structured materials audit brings clarity. In a Nextpack Materials Audit, we map your current packaging across ranges and channels, documenting substrates, laminations, inks, inserts and closures, as well as how each component is stored, assembled and disposed of in real life. From there, we identify quick wins, medium-term improvements and longer-term opportunities.

These insights help create a cohesive materials strategy rather than one-off decisions made pack by pack. It provides the foundation for choosing substrates confidently and consistently — the same thinking that underpins the sustainable material shifts explored throughout this article.

Common opportunities include:

• Consolidating similar materials to increase volume and reduce waste

• Removing redundant components that add cost but not value

• Simplifying complex constructions to improve recyclability

• Aligning packaging more closely with brand story and positioning

A materials audit does more than support sustainability. It can improve logistics, reduce production complexity and reveal cost efficiencies over time.

If you’re ready to review your materials holistically, you can book a Nextpack Materials Audit Session. It’s a detailed, guided process designed to help you understand what’s working, what can be improved and where the most meaningful sustainability gains can be made across your product range.

Sustainability claims are under greater scrutiny in 2026. A thoughtful review process helps ensure your packaging is not only well intentioned, but genuinely aligned with eco-friendly practice.

Conclusion – making eco-friendly packaging a practical reality in 2026

Eco-friendly packaging is no longer a future ambition. It is part of how modern brands operate. Customers, retailers and regulators now expect packaging to protect products, express brand values and minimise environmental impact all at once.

Moving toward more sustainable packaging does not require a single dramatic change. It is the result of many considered decisions: selecting recycled and recyclable materials, choosing vegetable-based inks, right sizing formats, replacing plastic with fibre, rethinking lamination, embracing mono material systems and reviewing your overall materials landscape.

Each step strengthens your position. Together, they create packaging that feels consistent, credible and commercially sound.

At Nextpack, this is our daily practice. We collaborate with brands across beauty, lifestyle, food and beverage, gifting, petware and retail to create packaging that is thoughtfully designed, highly functional and aligned with the world it ultimately enters.

If you are ready to explore what eco-friendly packaging could look like for your next range, we would love to collaborate. Together, we can map where you are now, identify the opportunities that matter most and design packaging that supports your brand, your customers and the planet in 2026 and beyond.